Large Area Projection Sintering

"Ascend has developed new proprietary additive manufacturing technology called Large Area Projection Sintering (LAPS). Think about printing in large areas simultaneously and not by scanning a single laser point. This provides unprecedented throughput while allowing you to print with the widest variety of materials in the industry. This technology is going to change how the manufacturing industry creates plastic parts."

- Dr. Justin Nussbaum, Founder and CEO

- Dr. Justin Nussbaum, Founder and CEO

The LAPS Difference

|

Print Faster

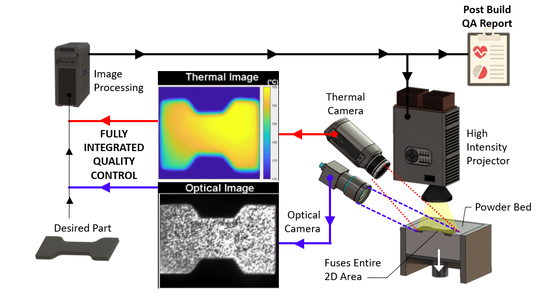

Large Area Projection Sintering uses projectors to melt a large area of the power bed surface, rather than using small lasers or nozzles as other technologies do. This allows LAPS to be the fastest 3D printing technology in the world, printing up to 200,000 parts per machine, per day. Wide Range of Materials Large technology enables a wider range of materials due to the unique benefits of using a projector to form the layers. This allows Ascend's systems to process materials from the ultra low-cost (~$9/kg) to high performance/highly filled materials for industries like space, aerospace, defense and medical. Quality Control The in-situ vision and control system monitors the print process and adjusts the sintering process in real time for best-in-class repeatability. This ensures consistency in every part as well as a quality analysis report on every part at no additional cost. In-process parameter tracking ensures and proves a repeatable production process to validate part consistency. |

WHAT WE DOAscend Manufacturing designs and builds industrial 3D printers for plastics mass production or low volume prototyping that will give you that unique edge to rise above your competition. Interested in life-long contract manufacturing services? That's us. Interested in purchasing a machine for in-house use? Give us a call!

|

HOW WE'RE DIFFERENTOur next generation machine incorporates has many disruptive technologies fully integrated. High performance parts, mass production, exotic materials, integrated quality control and assurance, we have you covered.

|

WHY USE ASCEND?Well, do profit margins matter to you? We can maximize these more than any other 3D printing company (we promise - contact us today!).

Designed and perfected with the world's experts in 3D printing. Each of our multiple technology innovations puts us light years ahead of everyone else. |